VKB Tech is one of the few companies which offers simulation services of bulk material behaviour during transportation, mixing, milling and crushing by Discrete Element Method DEM.

Discrete Element Method

DISCRETE ELEMENT METHOD is a computational method of modelling and simulation of particles during motion, their influence on the environment and mutual interaction. Available software like EDEM BulkSim allows simulation of almost any physical conditions prevailing during transportation, mixing or crushing taking into account the size and shape of particles, their density, elasticity and the ability to adhere. DEM simulation results deliver many valuable information for engineers like: displacements, velocities, forces and stress in elements/particles of moving medium.

DEM SIMULATION WILL ALLOW YOU TO:

Predict and improve performance of machines and devices

Choose optimal parameters and configuration of tools

Reduce energy consumption

Determine the real loads for design process

Avoid demurrage and breakdown

Increase service life of machines

Reduce the repair and service costs

Reduce dust emissions, spillage and wear

Identify regions of high wear

DEM Simulations are currently used in many industries for simulation and optimization of processes and for machine design. Below are examples of DEM simulation capabilities.

MINING AND METALS INDUSTRY

DEM Simulation in mining and metal industry allows:

Predict and improve performance of quarrying and handling processes in mining combines and conveyors

Determine optimal shape of excavator buckets

Determine the real loads acting on elements and next use it for FE structural analysis

Avoid problems with blockage in transfer chutes

Avoid demurrage and breakdown

Reduce energy consumptions by control of flow stream

Speed design and development processes of modern mining machines

DEM Simulation of coal transfer chute with gentle guide path of coal stream

DEM Simulation of bucket wheel excavator

PROCESSING OF MINERAL RAW MATERIALS

Discrete Element Method works very well in simulation of braking/separation and joining of particles. Thanks to the employed Explicit method and automatic contact detection algorithm between particles, DEM allows in an easy way to get reliable results.

Use of DEM for crushing, milling, and mixing processes simulation allows:

Geometry optimisation of tools, mixers, blades and buckets

Determine forces and loads acting on operating tools

Predict process efficiency

Verify many design configurations without the need of building prototypes

Speed development and design process

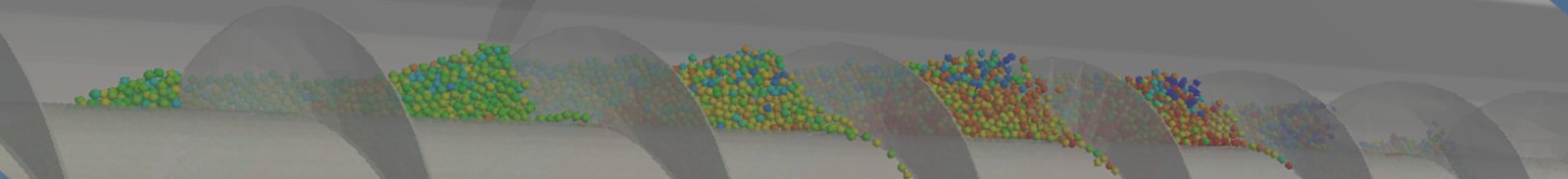

DEM Simulation of rock crushing process

DEM Simulation of mixing process

MATERIAL HANDLING EQUIPMENT

DEM simulations are more and more often used to design modern bulk material transportation system in mines, power stations and electro – thermal plants.

The use of DEM simulation allows:

Lower energy consumption by optimal selection of discharge angle and velocity of feed stream

Reduction of dynamic forces during material impact on belt

Reduction of dust emission by consolidating stream

Minimise material spillage

Avoid blockage of material in transfer chutes

DEM simulation of bulk material flow in transfer chute

The use of DEM simulations in the design process of transport systems

AGRICULTURAL MACHINERY

DEM simulation allows better design of agricultural machines like: combines (grain, potatoes, fruits, vegetables), fertilizer spreader and tillage machines, it helps:

Determine the influence of design on performance

Reduce the damage of crops

Accurately determine loads acting on machine elements that next can be used for structural calculations

Verify machine performance without the need of building prototype

Reduce R&D cost

DEM simulation of potato harvester

DEM simulation of fertilizer spreader

MULTIPHYSICS SIMULATION (FEA-CFD, DEM-MBD,DEM-FEM)

Multiphysics simulation of bulk material flow with heat transfer and fluid flow allows even more realistic simulation. Coupled DEM with FEA or CFD (fluid-structure interaction) gives much more information about processes, efficiency and influence of structure (mechanical and thermal loads). Multiphysics simulation is becoming the primary tool for verification of conceptual machines and designs at early design stage. Accurate prediction of loads during loading, transportation or processing of bulk materials is possible thanks to coupled DEM-CFD or, DEM-FEA simulations. Simple data exchange between software for bulk material handling and structural analysis allows engineers design robust & reliable machines without over design.

The use of multiphysics simulation in the design and development process allows to:

Determine the efficiency of various technological processes like: cooling, heating, drying, filtration

Accurately predict mechanical and thermal loads

Optimise the strength and weight of structure

Avoid breakdown during services or testing

Identify and secure places from wear and corrosion

Speed development and design process of reliable and energy efficient machines

Coupled DEM-FEA simulations (EDEM-ANSYS)

Multiphysics simulation of drying process of loose material

Coupled DEM-MBD simulations (EDEM-ADAMS)

Please contact us for more information or if you wish to talk to us about a specific project.